A-FRAME preparation line

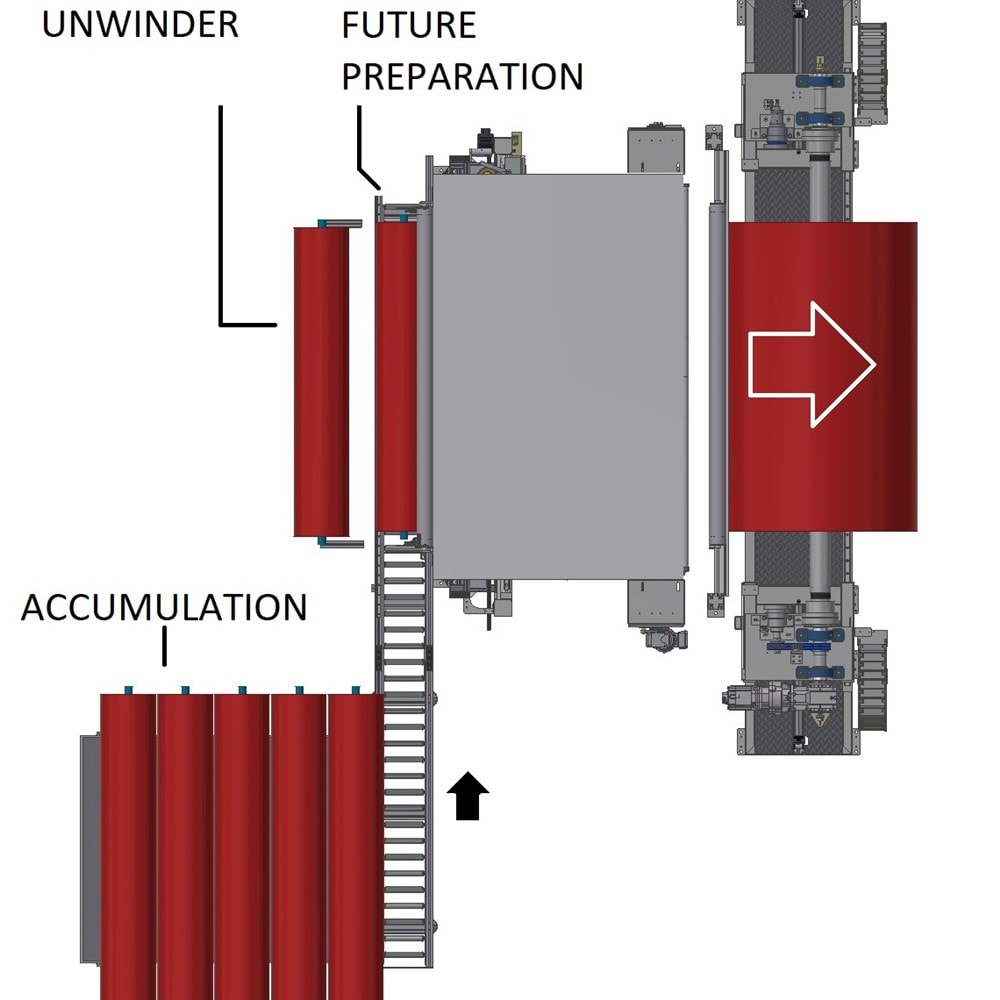

The machine mod. PRW is the ideal line for those production lines that require a compact but functional machine for joining and preparing big rolls on A-Frame trolleys with axial and tangential winding.

The fundamental concept underlying this machine, as with the entire line of roll preparation machines offered by COMATEX, is PREDICTIVE PRODUCTION: producing big batches while eliminating downtime and increasing the efficiency of the entire production department.

The joining system offered by COMATEX is the most complete on the market and easy to use for all operators, regardless of their experience in the sector. With the automatic advance and stop of the sewing machine, the operator simply positions the two fabric edges before the joining and that's it.

Like all COMATEX machines, the PRW is designed to the customer's specifications. The customer, working with the technical-commercial office, determines the mechanical limits of the rolls to be processed, the ideal fabric way, the most suitable edge alignment type, any intermediate processes the fabric must undergo, and the most suitable winding type.

A truly long list of available optional makes the PRW an indispensable machine for those looking for a simple yet truly complete preparation line.

SEWING TYPES

FLAT STITCHING

The flat stitching is perfect for all fabrics, delicate and durable.

The flat stitching allows the fabric to be wound without marking the other layers of the roll.

It also allows for use in machines where the stitching could get caught, such as in printing press heads.

It is available with a standard 18mm overlock stitch or a special overlock stitch up to 35mm.

CHAIN STITCHING

The chain stitching is perfect for fragile fabrics such as TNT (tessuto NON tessuto) subject to strong tension and allows you to join fabrics with a very internal seam line.

CUCITURA SOPRAGGITTO

The overlock stitching is used for fabrics with a variable structure that do not lend themselves well to chain stitch or flat stitching, such as lace.

What if you could earn 50% more?

The Future Preparation System is an innovative system that reduces sewing time by 25 seconds, allowing for a further 15 to 50% increase in productivity.

Thanks to an additional intermediate unwinding position, the operator prepares the next roll while the previous one is still unwinding and inserts the edge of fabric into the sewing track. During sewing, the roll is moved to the actual unwinder, ready to start as soon as the fabrics are joined.

This system saves up to 480 minutes per day (25 seconds per seam).

Fabric joining and quality control

The inspection table allows you to inspect the fabric with front and backlighting to highlight the texture. For our high-end machines, we use dimmable LED lights with a very high color index; the light can be white or adjustable from warm to cool.

The Join-rail overlocking track moves and sews the edges automatically; the fully-accessorized Ultra-kit version features triple stapling, an automatic chain-cutter, an extra cutter, and a strap to support the edges of lightweight fabrics.

The sewing track also allows you to join first choice fabrics, removing defective sections without affecting production.

Unloading area

The machine's exit can be in various forms:

• Roll on an A-frame carriage for woven or knitted fabrics

• Roll on cardboard, typically used for technical fabrics

• Free-fold for knitted fabrics

The winder can be combined with multiple systems: contact, non-contact, etc.

Before winding, the fabric is spread and aligned.

For fabrics with a felled selvedge, we can also include systems for zigzagging and trimming the selvedge or cross-cutting.

Cutting unit for tirmming

The perfect solution for trimming roll ends if they're too crooked.

It's also available in fully automatic and/or enhanced versions for very heavy fabrics.

Triple clamping for perfect alignment

Full-height clamping secures the fabric and prevents it from shifting during sewing.

Side clamping allows for perfectly aligned fabric edges and automatically stops the sewing machine.

The clamping can be manual (standard) or, for highly automated systems, with automatic fabric movement and tensioning.

Special needle clamping is also available upon request.

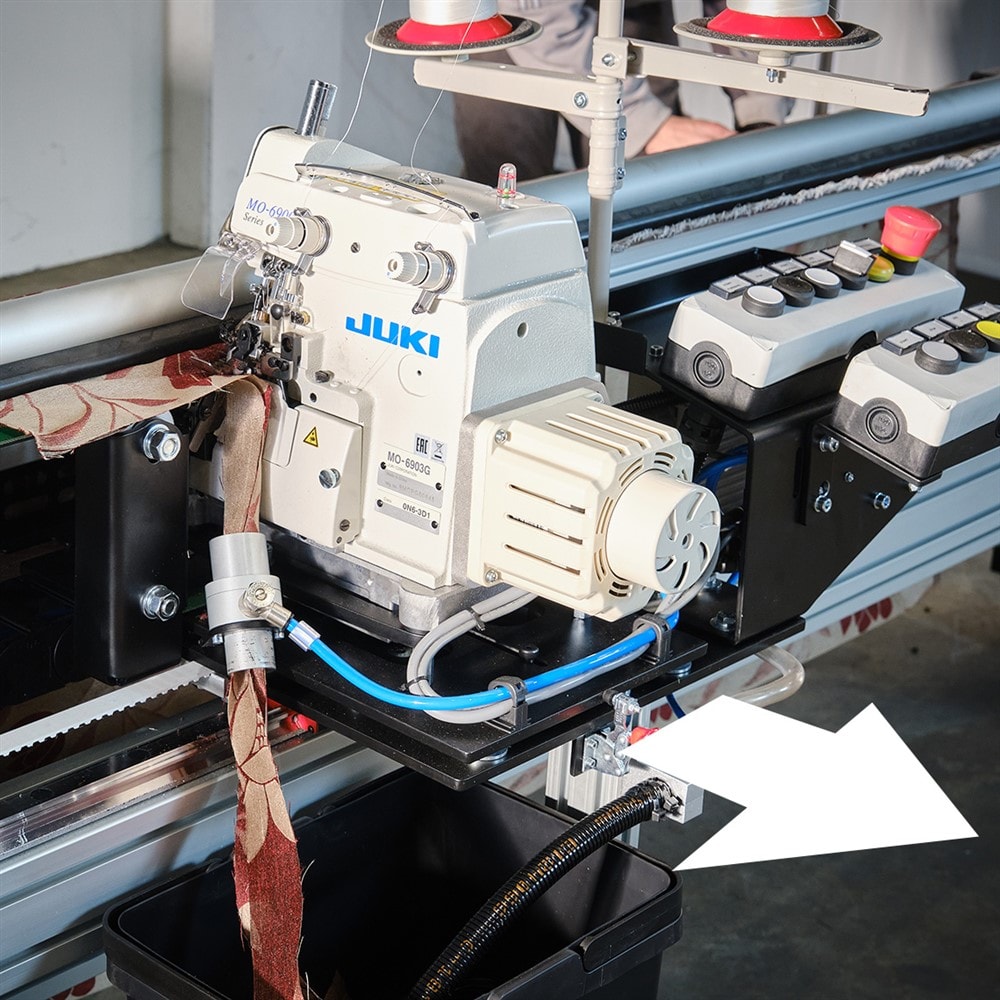

Automatic fabric-waste aspiration

The fabric waste is automatically sucked up and collected directly in a bin under the sewing machine, avoiding the operator having to throw it by hand into the bin every time, saving up to 30 minutes a day (3 seconds per stitch).

Automatic fabric support

The fabric is automatically supported beyond the stapling bar by a special belt.

This system is extremely useful for lightweight fabrics that would otherwise sag, and it allows for more uniform stitching.

It automatically guides the fabric continuously through the sewing machine, without operator intervention.

Automatic chain cutter and vacuum cleaner

The machine automatically cuts the chain stitch at the end of the seam, allowing you to speed up your work and save up to 30 minutes a day (3 seconds per seam).

Pull-out sewing machine

The sewing machine is mounted on sliding guides, you can take out the machine in 5 seconds without tools to thread the thread or change the needle.

Italiano

Italiano